What We Do

We offer the following services:

- Guidance, expertise (project preparation, design)

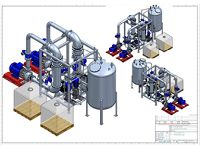

- Design (chemical;-machine;-oil industry, steel structure, pressure and hazardous material containers, appliances)

- Preparation of technical drawings (2D and 3D assemblies, factory drawings, detail drawings)

- Machine improvement (chemical appliances, improvement of meriton, other kinds of equipment, research and development)

- Machine renewal

- Machine products (special, unique, prototype, short; -middle series production)

-

Producing devices and equipment (grippers, centering devices, containers, filters, filter housings, separators, carrier devices,

mixing devices, mixing stations etc.) - Manufacture of steel structures (small;-middle;- unique structures, holders, railings)

- Manufacture of devices, equipment, containers, further modification or renewal of these goods

- Production of machine elements and components (for export, too)

- Cutting (turning, milling, drilling, grinding)

- Plate machining (cutting, bending, laser and plasma cutting)

Concerning workmanship, we can fulfil projects at field of work with our own team. We make all-inclusive services from design to installation.

- Machine installation

- Installation

- General workmanship

- Lending human resources

We started with fabricating spare parts of filtration units, as a supplier in the automotive industry. Today, with our partners, we can provide a full range of services.

Products where we have proven experience:

- vacuum filters,

- pressure filters,

- gravity filters,

- pre-coat filters,

- back flush filters,

- cartridge filters,

- resin traps,

- lime milk strainers,

- return pump stations,

- high pressure pump stations,

- holding tanks, (clean tanks, dirt tanks, pre-coat tanks)

- pipe work (system and main line pipes)

- steel structures

- etc.

Food industry technology

Zolend Ltd. has a lot of experience in technical design and production (pharmaceutical industry and food industry), and our technical partner’s strength is the up-to-date expertise of food industry technologies and the development of innovative products. Our co-operation has made it possible to create a product range (portfolio) that enables us to be present, uniquely, in the domestic and the international food industry markets with our complex services. During the co-operation of Zolend Ltd. and its technical partner, we have developed a vacuum drying technology and implemented a pilot plant whey concentration unit so far. We are constantly working on reaching a top quality standard and maintaining it. That must be, in our view, one of the most important targets for us.

Our technologies:

- Vacuum drying equipment

- Membrane technology

Biotechnology

The technical partners of Zolend Ltd. are the Biotechnological Incubator House of Debrecen University and Technovation Ltd. The great advantage of this consortium is the coexistence of biotechnological experience, test capacity and technical capacities.

Examples for the scope of biotechnology:

- Food industry

- Pharmaceutical industry

- Chemical industry

- Forage industry

- Environmental protection

Environmental protection technologies

Zolend Ltd. is committed to the research and development of environmental protection technologies. Our strategic partner in research and development is the Hungarian Academy of Science Institute of Materials and Environmental Chemistry. We design and implement complete environmental protection technologies and develop customised ones according to our partners’ technologies. The main areas are the following:

- Cleaning soil polluted by carbohydrogen with desorption technology

- Cleaning exhaust gas and extracted air issued in industrial processes with a catalytic air purifying technology

References:

- Optimisation of catalyst dispersion tank arrangement, expert opinion engineering service

|

plant production |

|

engineering service |

|

engineering service |

|

plant production |

|

plant production |

|

plant production |